What Low-Volume Injection Molding Means to Us

Have you ever been talking with a co-worker from a different department and realize that, while you both thought you were on the same page, you were actually speaking about two entirely different things?

A popular article from Harvard Business Review titled, “I Don’t Understand What Anyone is Saying Anymore,” expands on the idea that professionals rely on jargon, but many people may have different definitions of the same term. Having clear definitions of industry terms can reduce confusion down the line.

That idea is relevant when it comes to low-volume injection molding. Many custom injection molders use the term “low volume.” But when it’s time to determine if that aligns with your product development, prototyping, design validation, pre-production and full production needs, some original equipment manufacturers (OEMs) find that their definition differs from the injection molder’s.

Forum Plastics understands the product development lifecycle, and we have a clearly defined engagement model for low-volume projects or an iterative or continuous product development process.

Defining Low Volume

The obvious question is this: how do we define “low volume”? The answer is anything less than 10,000 pieces per year.

Supporting low volume has been integrated into every aspect of our business including engineering, project management, materials, and tooling. Project volumes do not have an impact on our lead times, and we are set up to handle multiple machine set ups and material change overs.

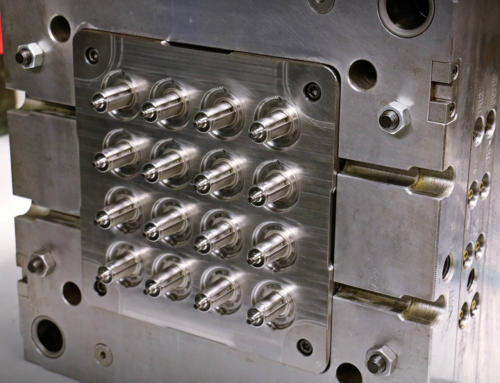

Hardware requirements and part assembly or attachment methods can impact tool costs through the addition of actions, lifters and slides. Some low-volume parts may require hand-loads to be designed in to eliminate complex side action, and Forum has the process and experience to handle this.

We purchase many different materials and engineered resins, and as a result, we stock many standard materials. Forum works with our customers through lot charges and other supply agreements, and we are flexible when it comes to special materials needs.

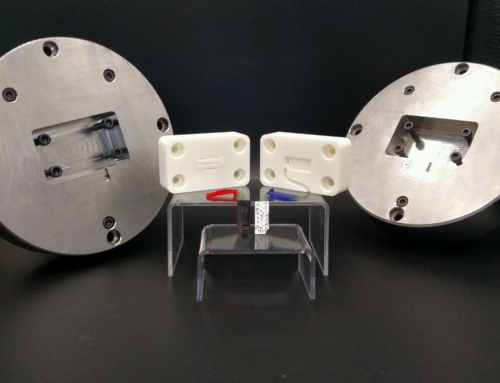

For low volumes not requiring immediate migration to production tooling, Forum offers 3D printing and SLAs as an option. We have also developed strategic partnerships to provide vacuum casting solutions.

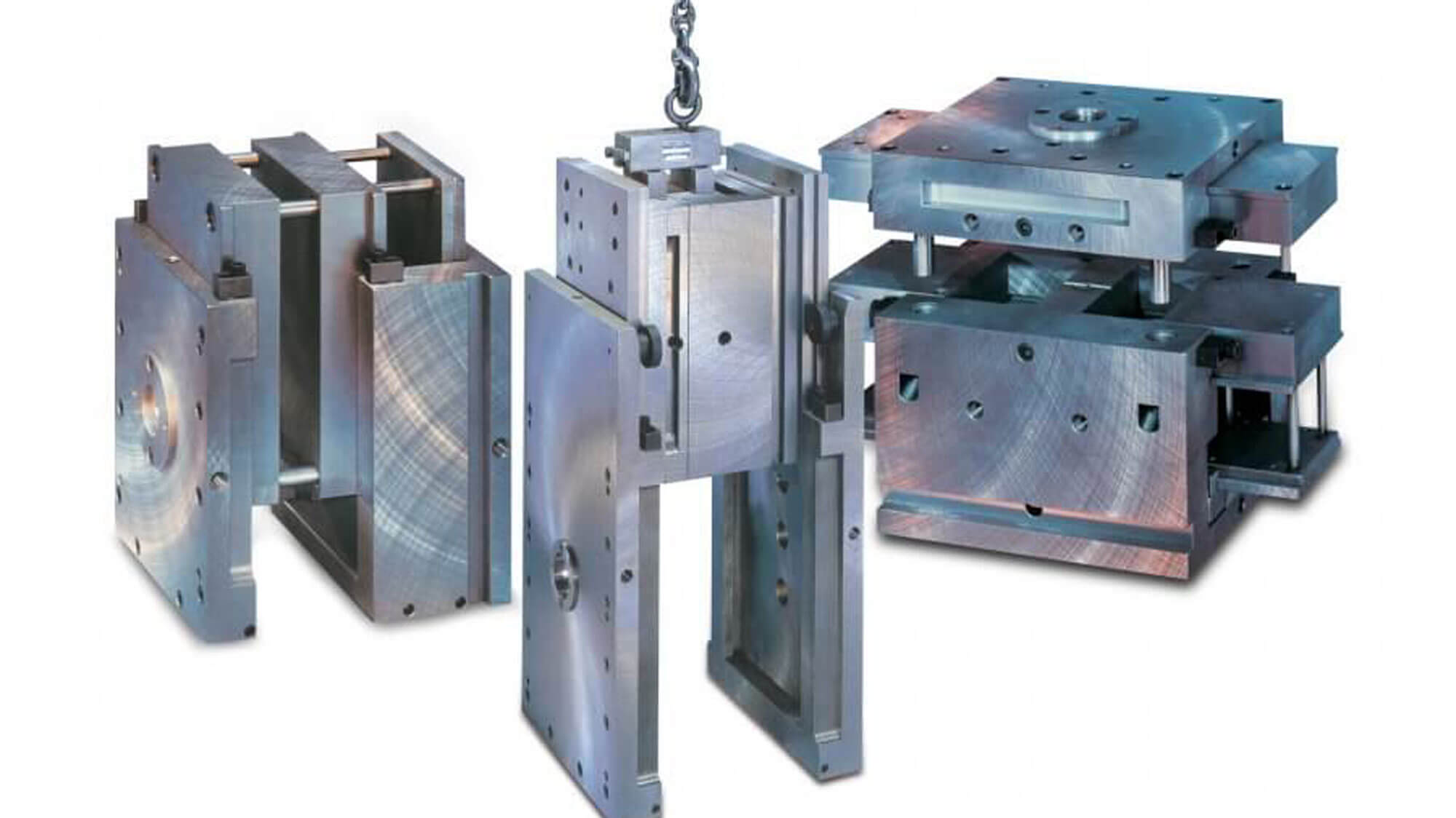

Custom Tooling Options

The ability to support low-volume tooling is also considered in Forum’s tool design and development. Forum does not make aluminum tools – only Class 101 and 103 tools using steel for our mold base. Master Unit Die Quick-Change (MUD) are a tooling option with steel inserts. Our proprietary custom frames are built to accept custom steel cavity inserts to keep your cost low and speed to market high.

All of these options ensure that your product has a high-quality solution that will produce a high-quality part.

Flexible Solutions to Meet Your Needs

With a customer-first mentality, Forum places a high value on long-term customer relationships. By developing a low-volume strategy to support product development for customers needing a solution for short-term builds or sustaining production, we have the solutions you need to meet your project timeline, volumes, and cost targets.

Learn more about how Forum plastics is expertly positioned to support your product development and low-volumes needs. Contact Doug Hungerford, Director of Engineering, for more information.

Stay Connected

Sign up to get updates from Forum