Process and People Result in Peak Performance in Supply Chain Management

Supply chain management professionals are often the forgotten heroes in a manufacturing setting. They run a careful balance between having the correct materials in the correct quantities and not holding too much cost-burdensome inventory. Having a well-defined process – staffed with excellent people – is the key to peak performance in any injection molding operation.

Process Driven

Forum Plastics understands that well-defined processes are critical for the production of medical and life science components and devices. While many molders can point to their scientific molding practices, validation and quality processes, and even program management, it’s important to know if their supply chain management processes are equally up to the task.

All too often, molders may be reactionary or transaction-based in their approach to materials management. In these situations, very little time and resources are invested in monitoring inventory levels, tracking material lead time fluctuations, pricing indices, monitoring customer forecasts and volume fluctuations. With today’s material shortages, increased pricing, extended lead times and disruption in transportation and logistics, having a focus on supply chain management is increasingly important to maintain a continuity of supply. Our supply chain and planning team works very closely with program management from the very beginning of any new project.

Key questions are asked at the onset of a program:

- Is the specified material similar or an engineering offset to a resin already used by Forum?

- Is there any supply constraint with the specified material and is the customer open to an alternative or multiple sourcing options? What other items on the BOM (such as labels, packaging, pad printing ink, bags or liners) might be a supply chain constraint and how best can Forum help mitigate that?

Once a project has migrated from the development stage into sustaining production, program management, production, customer service and our materials department maintain a continued process and need-based assessment to ensure continued support and strong communication flow to our supply and commercial partners. There is an ongoing dialog that focuses on long-term forecasting, monitoring of lead times and weekly reporting directly to our customer base.

This includes outlining:

- Inventory levels, safety stock and Kanban

- Monitoring open orders and P.O. release signals

- Accurate forecast/demand management

All this is to help you meet your production requirements and mitigate risk to material availability. This ongoing communication helps ensure that there are no “surprises” that a delivery commit date will not be met.

People Driven

Forum’s materials manager, Anne Yost, has over 20 years of experience in commodity management for custom injection molding organizations. Anne’s industry experience has led to the development of many important and strategic partnerships with compounders, distributors and resin suppliers which are often critical to Forum’s supply chain success.

Anne shares, “We recognize the supply chain challenges we faced were globally prominent and since many of our customers are in the life science and medical device space, we had an important role to ensure continuity of supply for these life-enhancing and life-saving devices. Given the experience and relationships our team holds with our material, distribution and supply partners, we worked together to minimize impacts to our client base. Without our material and supply alliances, this never would have been possible, and we are incredibly thankful for the cohesive teamwork that our vendors provided to us and, in turn, to the medical device community.”

Our teams consistently review industry data to stay on top of emerging trends and supply chain volatility. Recently, a medical device customer was facing the possibility of a production stop and line down unless Forum could find an alternate and approved source for this component. We worked with our material partners to find an engineering offset that not only maintained continuity of supply, but also led to a material price reduction. Forum’s material team gathered the required information to present to the customer to support this alternative and safeguard the supply chain continuity.

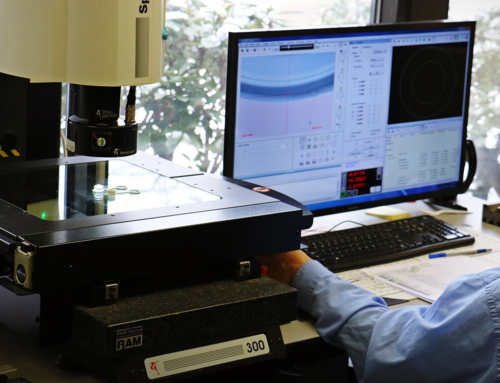

Based upon Forum’s unique and specialty service offerings, such as micro molding, product assembly, automated pad printing and metrology services, having proficient and well-trained staff available to support critical medical and life science products is key to their success. Focusing on employee training, retention and engagement are fundamental factors to both Forum and their customers. Even in uncertain times and a challenging labor market, we have been able to operate six days per week in each of the three shifts.

Peak Performance

An efficient supply chain requires a concerted effort between the materials team, engineering, program management, customer service and operations. The last two years have presented all manufacturers with a unique and difficult chapter.

Gleny Pinales, Operations Manager at Forum Plastics, said, “Although the last year was challenging with regards to material shortages, delays, and labor related variability, our commitment to meeting our customers’ requirements and timelines remained a leading focus for our group. It took the dedication, diligence and hard work of our entire team, and we are proud to have maintained an on-time delivery rating of over 90%.”

Gleny and the operations team proactively evaluate manufacturing bottlenecks and areas where automation and robotics may reduce labor, improve efficiencies and increase production output. Investing in both people and technology has led to operational efficiencies that have benefited both Forum and our customer partners.

Ultimately, actions speak louder than words. It is a testament to the process and the people that Forum was able to achieve a 92.3% on-time delivery to our customers in 2021. We have the infrastructure to manage the contracts, logistics, warehousing, and cash flow to provide full management of the entire supply chain on added value projects.

Contact us today to learn how Forum can assist you with your next component or medical device.

Stay Connected

Sign up to get updates from Forum