Metrology Services: Value-Added Services for Injection Molding

Common challenges in medical device development for injection molding include part and product validation, as well as the timely completion of first article inspection (FAI). Completing the FAI is one of the last critical steps so that the molded components can launch into full volume production. Any delay in mold and part verification during the review and approval of an FAI has a direct impact on the delivery, assembly, and general product availability, and it can have an adverse effect on capturing market share and generating revenue.

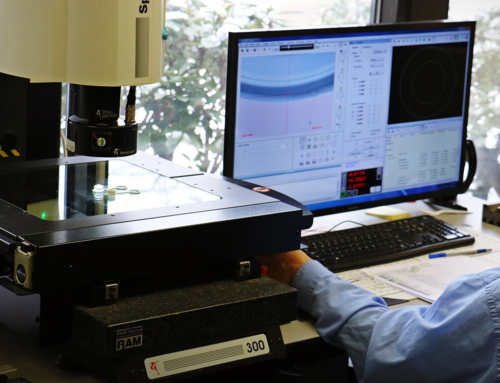

Like many injection molders, Forum Plastics offers traditional hand measurement services, such as calipers, micrometers, and drop indicators, vision inspection utilizing Micro Vu, RAM, and Keyence inspection systems with touch probe capabilities. Because FAIs and the need for precision are critical, Forum Plastics has made significant investment in equipment for our metrology lab. This includes a CT scanner which is an invaluable tool for many of our OEM customers needing to quickly get parts approved for production, in addition to troubleshooting manufacturing issues and eliminating costs and guesswork.

Using our CT scanner, Forum can measure parts, especially small components, without the need for cross-sectioning or damaging the part. Using this technology, we can also check for internal defects and compare the geometry to the CAD model.

Our metrology lab leverages CT scanning capabilities to use industrial computed tomography equipment. When determining the method of inspection, there are several factors to consider:

- Material to be measured – If the part is made from softer materials, it may require non-contact inspection with a vision or CT scanner system.

- Part tolerances/resolution required – Each device/system used has a limitation on how accurate it can measure a part.

- Part size/shape – Complex parts can be easily inspected on the CT scanner, but the inspection volume is limited and larger parts can’t be inspected using this system.

What are the benefits of leveraging Forum’s CT services?

The first part off of a mold is the true test to confirm that the process and mold meet the desired outcome. A first article inspection carefully measures that the test part is in conformance in both size and shape to the original 3D model. The process of validation and FAIs can involve multiple pieces of equipment and systems and may take hundreds of hours of checking geometry – especially if you are inspecting a multi-cavity mold. This can sometimes take weeks, even months.

But leveraging a CT scanner – especially for projects with very complex parts – can reduce that time significantly, and after all, time is money.

What inspection services does Forum offer?

Forum offers a full range of inspection and documentation services, including

- First article inspection reports (FAIs or FAIRs)

- Capability studies

- Measurement system analysis (MSA)

- Gage repeatability & reproducibility studies (GR&R)

- IQ/OQ/PQ

- Production part approval process (PPAP) documentation

What are the key advantages of using Forum’s metrology services?

While some may believe that all validation services are equal, Forum has made significant investments in key technologies to meet customer requirements for high-quality products.

- Forum Plastics is the only local injection molder to offer a CT scanner for its inspection services. Our metrology team is dedicated to new part validation inspections. We do not mix our inspection services with in-process production inspection. This allows us to have the resources available to complete the validation work promptly.

- Forum utilizes many templates for our FAIs and Capability Studies as well as programs for our inspections. Programs are developed during the tool design phase with 3D printed models developed in-house on our 3D printers. This allows us to work out the details of the inspection program prior to molded parts being produced. Because Forum has developed these programs, you can have the confidence and assurance of a consistent outcome.

- Our staff is trained in many aspects of quality/manufacturing systems, including multiple levels of ASQ, Blueprint reading, GD&T, Micro Vu and RAM optical basic and advanced training as well as CT scanner software/hardware operation. We offer metrology services to all of our customers, even if the product was not molded at Forum.

Get Started With Forum

To learn more about our quality systems, validation protocols, metrology lab, and services please contact Andrew Butkus, Engineering Manager at Forum Plastics.

Stay Connected

Sign up to get updates from Forum