Save Time and Money With Forum’s Prototyping Solutions

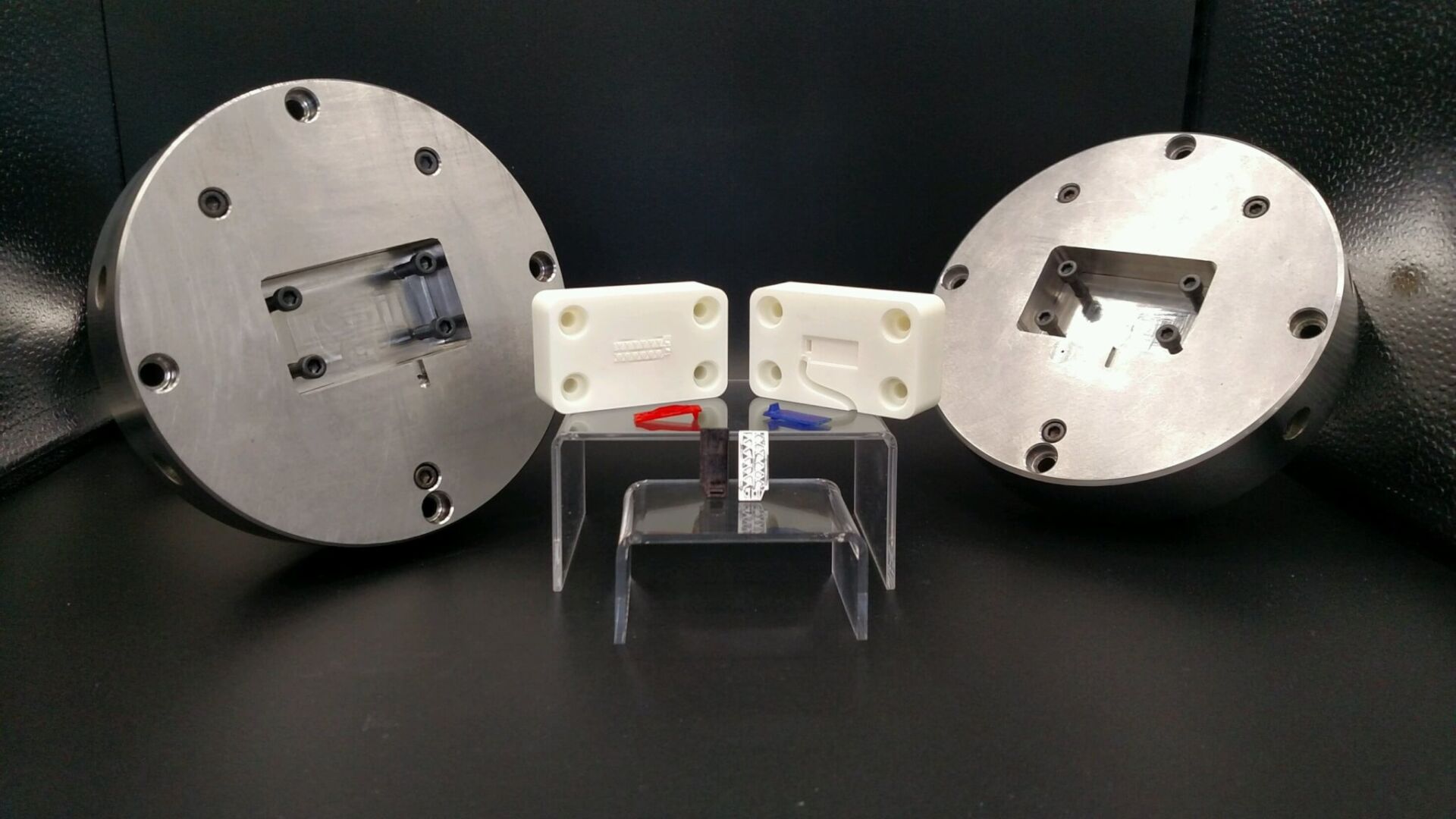

To save time, many customers leverage Forum’s ability to 3D print to create mold inserts that can make fast, functional parts. The key benefit of this capability is that it allows OEMs to quickly run parts with the engineered resin that will be used in production. Additionally, when it comes to tooling, Forum has invested in a modular molding system that keeps the upfront tooling investment lower. These cavity block solutions are Class 103 tools that can support low-volume, limited-production runs while meeting production quality standards. Learn more about Forum’s custom tooling options here.

Forum is your Prototyping partner. We are committed to supporting our customers early-stage development programs.

There are many reasons why an OEM may consider prototyping before launching a tool build for production parts. Often, rapid prototyping is used to validate a design and test the product form and fit to better understand device assembly and interoperability modifications that may be required. Other times, prototyping is a bridge to production when you need real molded parts immediately while waiting weeks – or sometimes months – for high cavitation tooling to be completed. Forum offers multiple options, leveraging various technologies, to help you get parts faster and cost-effectively, as well as accelerate the product time to market.

Complementary Capabilities & Markets

Forum offers a full suite of secondary services for both prototypes and production, including pad printing, threaded inserts, machining, and assembly.