Assembly Services: Moving Up the Value Chain

Have you ever attended a sporting tournament and considered all the logistics that needed to be coordinated to make that tournament happen? When planning a sports event, an event manager must oversee a variety of moving parts, such as securing sponsors, hiring referees, designing t-shirts, booking photographers, creating signage, and checking sound systems.

Managing all of these moving pieces is no small task, so when an organization is able to hire a respected and established event manager who knows the industry, this provides one key contact who can streamline planning and logistics.

For this same reason, it’s no wonder why OEMs tend to look for injection-molded partners that can do far more than simply build a tool and mold a component.

The Benefits of Higher-Level Assembly Services

Commodity managers, mechanical engineers, and project managers often need a molding partner that can move up the value chain and assist them with a higher-level assembly. The advantages of assembly services from your molding partner are significant.

Here are the three main benefits of assembly services:

- Labor Cost Reductions

Other than resin and purchased materials, labor is typically the biggest cost driver in a high-level assembly (HLA). Every time an operator or assembly touches a part, your supplier must account for that cost or labor center. Additionally, if you have one supplier mold the part and then ship it to another supplier to add components or bring it up to a high-level assembly, you add touchpoints and margin stacking. If a part needs to be packaged and shipped to another vendor for value-add work, you’re adding the cost of packaging, freight, unboxing, and assembly – then re-packaging it again for order fulfillment.

Working with an injection molder that can do multi-part assembly and post-molding operations under one roof can alleviate some of that additional cost. - Improved Quality

As mentioned above, every time an operator or assembly is touched, you’re not only adding labor, but you’re also increasing the possibility of a quality issue. If your molding supplier cannot offer value-added services or manage the BOM to supply an HLA, you run the risk of scratches, abrasions, damage, or defects.

This is especially true if the part is shipped to multiple vendors prior to landing on your dock. - Vendor/SKU Reductions

In the current business environment, most OEM’s don’t have the time, resources, or budget to add to their existing supply base, let alone add new suppliers. Many companies are focusing on vendor reduction and consolidating their business with suppliers that can move up the value chain and provide them with additional services.

Working with an injection molder that provides extensive secondary operations, supply chain management, and vendor-managed inventory (VMI) services allow you to consolidate your supply base.

All in all, assembly services can provide labor cost reductions, vendor reduction and consolidation, lowered end-to-end supply chain costs, improved quality, and shorter lead times.

A Supply Chain Partner to Help Reduce Labor Costs and Lead Times

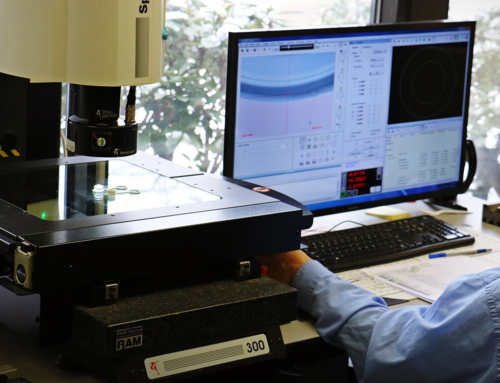

Forum Plastics has extensive experience and project managers who can provide coordination and know-how to build higher-level assemblies (HLA). We support our strategic partners with providing multi-part assembly of components. In addition to pad printing, medical and sterile packaging, and ultrasonic welding, Forum offers services and capabilities beyond just a precision-molded component.

To learn more about how Forum Plastics can assist you with multi-part assembly leveraging our secondary operations, supply chain management, and VMI solutions, please contact Doug Hungerford, Director of Engineering, to learn more.

Stay Connected

Sign up to get updates from Forum